What Technical Specifications are practiced by Schedule 20 Steel Pipes in Industrial Applications?

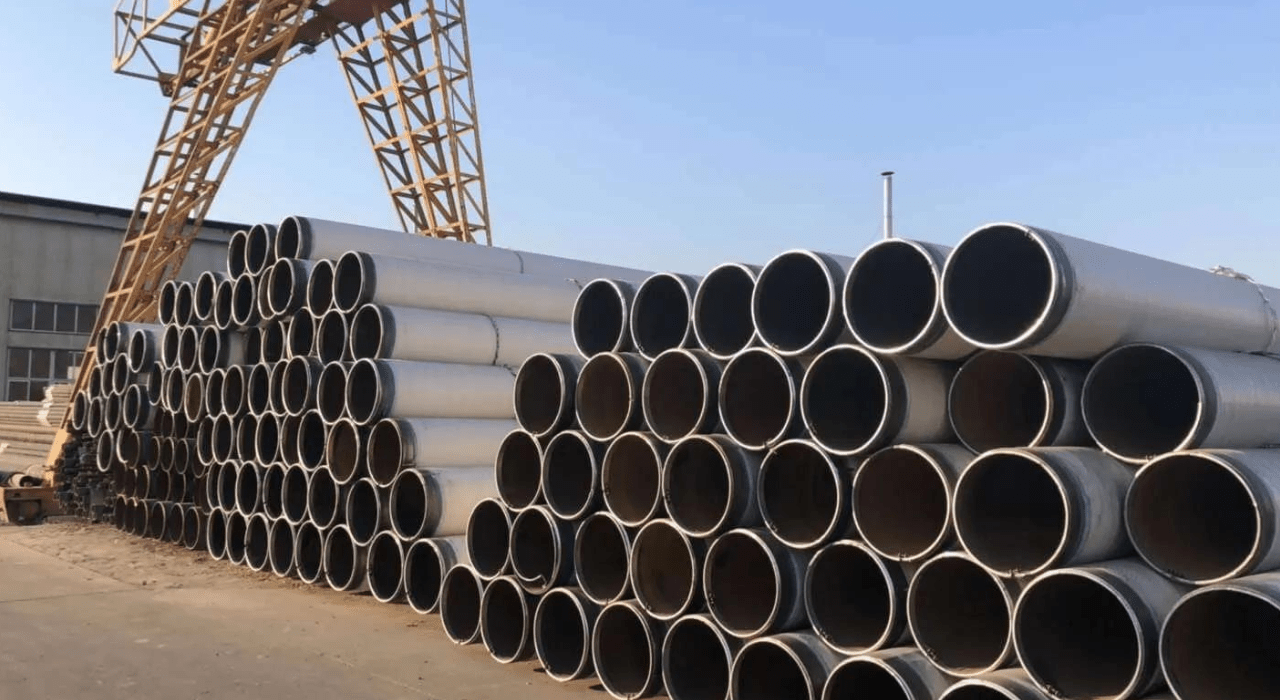

Among the various types of steel pipes, Schedule 20 pipes stand separated as a renowned choice for low-pressure applications. Schedule 20 pipes are somewhat meagerly walled, which makes them savvier and lighter contrasted with higher Schedules. This makes them especially appropriate for applications where high strain is certainly not an essential concern, yet material toughness, erosion obstruction, and simplicity of establishment are fundamental.

These pipes are frequently produced using carbon steel and utilized in applications going from water supply frameworks to central air frameworks. While not appropriate for high-pressure conditions, Schedule 20 steel pipes succeed in circumstances where the material stream rates are moderate. In this article, we will investigate the schedule 20 steel pipe technical specifications and the advantages of picking Tuspipe for your modern requirements.

Schedule 20 Steel Pipes Technical Specifications

Wall Thickness

The most distinctive component of Schedule 20 steel pipes is their slight wall thickness. While this makes them less reasonable for high-pressure applications, the decreased thickness adds to the general gentility and cost viability of the pipes. The wall thickness of Schedule 20 steel pipes is for the most part around 0.250 crawls for bigger measurements and can go as low as 0.218 creeps for more modest breadths.

Diameter Range

Schedule 20 steel pipes are accessible in a large number of breadths, regularly beginning from 1/8 inch and going up to 24 inches or more. The interior width is urgent as it decides the pipe’s stream limit with regard to shipping fluids or gases. A bigger width takes into consideration higher stream rates, making Schedule 20 pipes flexible for various modern necessities, from water transport to air dealing.

Material Composition

Carbon steel’s inborn properties make Schedule 20 pipes profoundly strong, even in less demanding conditions. Also, a few variations might contain modest quantities of copper to further develop erosion obstruction.

Temperature Tolerance

Despite their slender walls, Schedule 20 steel pipes can deal with an expansive scope of temperatures, making them reasonable for various low-pressure modern applications. Carbon preparation itself can get through temperatures between - 29°C to 427°C or - 20°F to 800°F, contingent upon the combination organization.

Corrosion Resistance

While Schedule 20 pipes produced using carbon steel are not innately consumption-safe, they can be treated with defensive coatings like galvanization, epoxy, or paint. These coatings add a layer of safeguard against erosion, especially when the pipes are utilized in conditions where dampness or synthetic compounds are available.

Pressure Rating

The pressure rating of Schedule 20 steel pipes is moderately low, given their dainty wall thickness. While the specific pressure rating relies upon factors like pipe measurement, wall thickness, and material creation, Schedule 20 pipes are for the most part evaluated for lower pressures, typically under 300 PSI. This makes them appropriate for frameworks where the strain requests are moderate, like water dissemination, fire insurance frameworks, or low-pressure gas pipes.

Advantages of Picking Tuspipe for Schedule 20 Steel pipes

Given are the advantages of choosing Tuspipe for Schedule 20 steel pipes:

High-Quality Assembling Standards

Tuspipe is known for sticking to the best assembling principles, guaranteeing that each Schedule 20 steel pipe created meets or surpasses industry necessities. The organization utilizes progressed producing methods like ERW and HFW to make pipes that are steady in distance across, wall thickness, and material strength.

Customization Options

One of the significant benefits of picking Tuspipe for your Schedule 20 steel pipe needs is the capacity to tweak the pipes as per explicit task prerequisites. Whether you want a specific breadth, wall thickness, or explicit coatings to improve consumption opposition, Tuspipe offers adaptable customization choices. This permits organizations to source pipes that fit impeccably into their frameworks.

Competitive Pricing

Notwithstanding offering great items, Tuspipe keeps up with cutthroat valuing, making their Schedule 20 steel pipes an affordable decision for low-pressure applications. The organization accomplishes this equilibrium by advancing its assembling cycles and utilizing mass creation to bring down costs. This cost-proficiency makes Tuspipe an appealing choice for organizations hoping to diminish material costs without settling on quality.

Sum Up

Schedule 20 steel pipes are a well-known decision for low-pressure applications in different enterprises, offering an equilibrium of sturdiness, cost-viability, and simplicity of establishment. While their more slender walls limit their utilization in high-pressure conditions, they succeed in less requesting applications, for example, water supply frameworks, central air establishments, and light-obligation underlying parts.

Their specialized particulars, including wall thickness, material sythesis, and temperature resistance, make them a flexible and dependable choice for various modern necessities.