Modern industries rely on X-ray technology to find problems in components while checking their structures and material properties for different applications. X-ray systems help industries from aerospace to medicine by checking quality control with sharp focus and fast results. When quality assurance is not implemented correctly, X-ray inspection systems cannot produce consistent, dependable, regulatory-compliant scans.

X-ray systems function better through Quality Assurance by stopping mistakes, improving image quality, and following safety rules. This report studies how quality assurance supports high-tech X-ray inspection systems in working better and producing reliable results.

Quality Assurance helps X-ray systems function better.

Quality assurance in X-ray inspection consists of planned activities to keep X-ray systems safe and working correctly while maintaining precise results. It differs from quality control in that it takes a proactive approach by stopping problems before they start.

Organisations achieve top quality by checking equipment accuracy, validating system software, maintaining essential parts regularly and following approved operational guidelines. These standards help X-ray systems perform reliably in all types of imaging tasks.

Quality Control Measures Help Create Accurate X-Ray Pictures

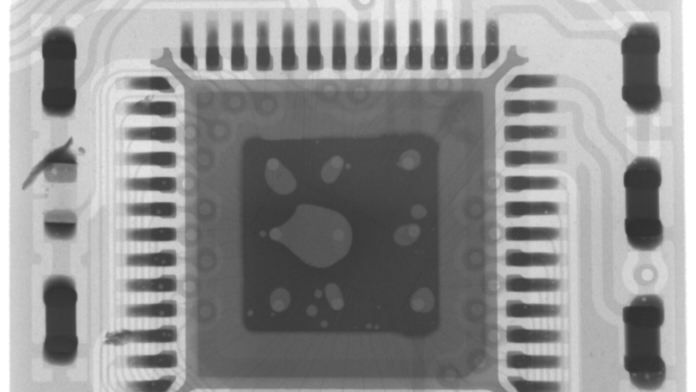

Imaging technology must produce precise images to identify minor defects in industrial parts and electronics. Correctly identifying defects depends on seeing clear pictures since poor image quality affects product safety. QA protocols help eliminate false test results by using advanced calibration systems to show more explicit images.

Testing and scheduled checks help X-ray systems deliver their best possible contrast and image details. The system automatically fine-tunes imaging settings to industry standards, which helps prevent errors and makes medical results more precise. The quality control program checks that radiation exposure levels and environmental temperatures stay within safe limits.

Regulatory Compliance and Industry Standards

Industrial facilities that use X-ray technology must also follow industry standards to ensure that the technology meets safety and effectiveness requirements while staying within legal limits. Manufacturing and operating X-ray systems must follow ISO, ASTM, and FDA standards.

Organisations follow healthcare regulations through strict quality assurance programs that test and accredit their systems. When companies do not follow the rules, they face legal and financial penalties and problems with product quality. Economic sectors must follow strict safety procedures to prevent hazards and keep their practices following government rules.

Software and Hardware Reliability in X-Ray Systems

The quality of software matters most when X-ray machines need to examine many images at once. QA helps keep software applications free from technical difficulties and security vulnerabilities. Updates and testing procedures help prevent issues before they affect how well X-ray systems detect defects.

X-Ray system maintenance depends on reliable hardware components. Regular checks and part replacements through preventive maintenance help keep X-ray imaging equipment running longer. When organisations adopt QA-driven maintenance programs, they avoid system breakdowns and help their operations run smoothly.

Automation and AI in Quality Assurance for X-Ray Systems

Artificial intelligence and machine learning make X-ray inspection quality control systems more effective. Advanced fault detection systems with artificial intelligence find and identify defects more precisely than humans can at high speed. Machine learning algorithms process big data to update inspection settings while lowering the frequency of wrong detection results.

These advanced systems produce consistent and dependable defect results while eliminating human mistakes and speeding up work processes. Adding AI technology makes X-ray inspection work faster and better at identifying issues, plus helps predict when system parts need maintenance. The ongoing research in AI-driven quality assurance will keep improving the speed and accuracy of industrial X-ray inspection systems.

Challenges and Solutions in Implementing Quality Assurance for X-Ray Systems

High-tech X-ray system QA maintenance faces many barriers, from technical restrictions through operational waste to government requirements. The X-ray imaging components deteriorate with age, decreasing their ability to deliver clear images and precise diagnoses.

Industrial sectors use advanced maintenance solutions, automated calibration tools, and live system monitoring to solve these problems. A regularly running staff training program helps operators master quality control procedures and system anomaly management. Updates to our systems’ software and AI technologies help us meet new requirements in industrial X-ray inspection operations.

Conclusion

QA systems make X-ray inspection equipment safer to use, help reduce downtime, and improve system performance. Quality assurance helps industrial X-ray technology perform better by delivering quality images that follow the rules while protecting hardware and software.

Advancements in machine learning technology will make X-ray inspections more precise and reliable in the future. Companies that put quality assurance at the heart of their X-ray system operations will see better business performance combined with lower risk and better product quality. The importance of QA in X-ray inspection systems grows stronger as technology develops across all business sectors.